Description

EBC® – Stage 5 Superstreet Brake Kit for Mercedes G55 AMG 5.5L 2010

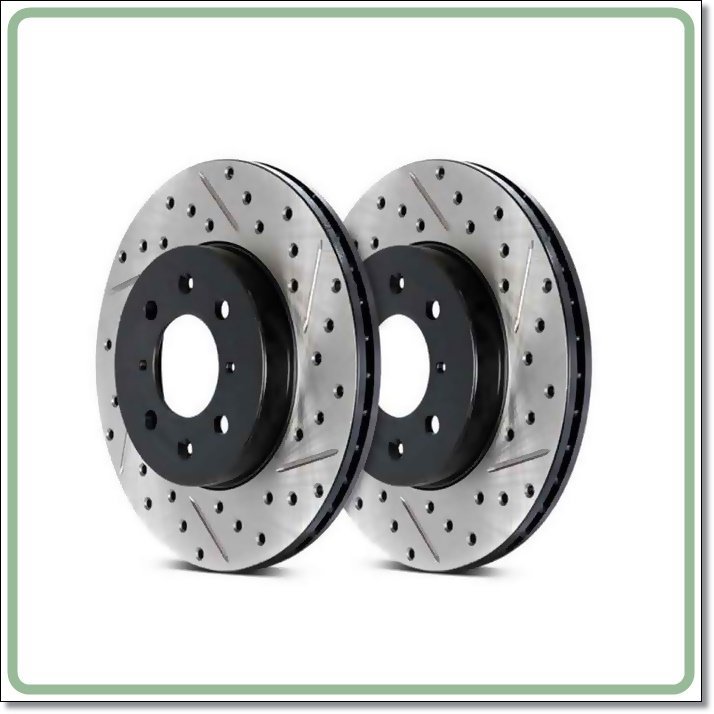

Mercedes G55 AMG 5.5L 2010, Stage 5 Superstreet Brake Kit by EBC®. The EBC Stage 5 SuperStreet Brake Kit is designed for those looking for heavy-duty high gripping pads and rotors. Thanks to the 4000 Series Yellowstuff Street and Track Pads matched with some of the coolest rotors you’re sure to get smooth, consistent braking every time you hit the brake pedal. The anodized layer is designed to disappear in the area that the brake pads contact the rotor.

– Round indents in the rotors surface further increase cooling without the risk of cracking that drill-through holes pose

– Angled slots on rotor surfaces allow superior expulsion of heat, water, brake dust, and friction gases

– Black GEOMET and NITROTHERM™ anti corrosive finish

– Brake rotors are unidirectional to the left and right side of your vehicle to maximize effectiveness

– EBC recommends a 500 mile break in period with lighter braking application

– 6-month/3,000 mile manufacturer warranty against premature rotor wear under normal driving conditions

– Engineered to better resist mud, sand, and grit that accumulate on brakes during off-roading

– Designed to provide an optimum combination of street and racetrack performance

– Unique composition allows high braking friction when brakes are cold

– Features a cold friction rating of 0.5

– Backing plate and side edges of brake pad are yellow powder coated for resistance to corrosion

– Pad surfaces have chamfered edges to reduce contact against rotor lip that forms over time and causes squealing

– Center gap allows for proper heat expansion of brake pads

– Built in noise-reducing shims

– Patented Brake-In™ red pad surface coating provides better grip during the first 100 miles after new pads are installed

– Patented Brake-In™ red pad surface coating scours off any existing glaze or heat spots from brake rotor surface for more even surface mating

– 6-month/10,000 mile manufacturer warranty against premature pad wear under normal driving conditions

– Provides equivalent performance to GG-rated brake pads

Benefits:

– Slots reduce stopping distances in wet weather

– Slots help to increase pad bite and improve air circulation

– Slots create an escape route for debris, dust, gases, and water

– Slots clean and de-glaze pad surface for optimum pad coefficient of friction

– Dimples are resistant to cracking compared to drilled holes

– Dimples reduce the stress on the pads and improve heat dissipation

EBC pioneered brake rotors with dimple-drilled round indents decades ago to provide a solution to cracking problems that sometimes plague perforated rotors operating under high stress and heat conditions. What makes the – 3GD Series Dimpled and Slotted Sport Rotors superior is the presence of both these dimpled indents and straight vent slots. Combined, they provide the superior expulsion of heat, water, brake dust, and friction gas that is needed to keep rotors cool and functional during street performance driving in any weather. Additionally, 3GD rotors feature a wider vented aperture for air to pass between both rotor sides, so metal expands evenly during use and the chance of warpage is minimized. 3GD rotors are designed for use with EBC Greenstuff 4×4 brake pads, Greenstuff 2000 compact car pads, Yellowstuff heavy duty 4×4 brake pads, and Yellowstuff / Redstuff pads created for shorter high performance street or track runs and drifting. 3GD brake rotors are anodized to prevent corrosion, and rotors should be fully ready for use after the first 500 miles of moderate brake application.

EBC Yellowstuff 4000 “R” Series Full Race Brake Pads deliver fade-free performance on the racetrack, effective grip during street racing and drifting, and comfortable, easy-to-use operation under normal driving conditions. From the Swedish Camaro Cup to Mazda MX5 Miata competitions to SCCA challenges, Yellowstuff Racing Series pads are favored by drivers across a wide range of racing cup events that require the use of stock OEM brake caliper systems. Why? The more exotic aramid fiber construction of Yellowstuff pads is known for its ability to maintain easy controllability and high grip levels at any temperature while also resisting heat buildup and brake fade under severe conditions. EBC conceived the Yellowstuff 4000 line for lighter Japanese vehicles as well as heavier, high-horsepower sedans typically found travelling German autobahns at triple-digit velocities.

If you’re installing Yellowstuff 4000 “R” Series Full Race Brake Pads with new brake rotors, you’ll find down the road when the time comes to replace the pads again, rotors will still be usable enough to last through another set of brake pads. And if you are installing EBC pads without replacing rotors, pre-chamfered pad edges will mate perfectly against the grooves and lips that normally form on the rotor surfaces, so the meat of the pad makes contact against the rotor center where it counts. These pads also feature a red top layer coating designed to scour glaze and hot spots off worn brake rotors during the break-in process. As it does that, the coating also serves to provide a higher level of grip to counteract low friction levels that exist before bedding is complete. Built-in shims ensure any high-frequency vibration is absorbed rather than transferred as squealing noise, even under the most extreme weather conditions. EBC backs their replacement brake pads with a 6-month or 10,000 mile warranty against premature wear under normal driving conditions.

Founded and based in the United Kingdom, EBC Brakes is a premiere producer of brake components for passenger cars, trucks, buses, motorcycles, ATVs, and even scooters. EBC brake pads and rotors are preferred by fleet operators of emergency vehicles, livery cabs, and by discerning racers all over the world for the effective grip, superior lifespan, resistance to heat buildup, and proper fit they deliver. From the company president down to every employee, EBC strongly believes that brake components that are truly superior must be constructed from the most effective materials and also offer the lowest environmental impact possible. Likewise, EBC will never put their name on any products that cut corners in development, quality control, or are manufactured using sweatshop working conditions where human rights are not valued. When you want the best, most responsible brake components that meet or exceed OEM specification without dealer OEM markup, EBC Brakes is the only name you need to know.

Notes: This part may be considered a Special Order if custom-made, low volume, or not something we generally stock. There may be a cost for Air Freight, Customs, Taxes, and Duties. Your card will not be charged during Checkout; only an Authorization will be obtained. If necessary, we will contact you with details before processing the order. Please review our Terms & Conditions before ordering.

Reviews

There are no reviews yet.